Extrusion machine

Types of extruders

| Extruder Type Table | ||||

| Single-screw extruder | Non-vent type | Pipes, tubes, deformed products, molded products | PMS20~90 MS100~300 | |

| Sub-extruder (mobile) | MVS20~50 | |||

| Vent Type | For granulation and sheet molding | PMSV40~90 MSV100~180 | ||

| Twin-screw extruder | Conical type | Bidirectional rotation (slow rotation) | Hard PVC (or high viscosity resin) pipes, tubes, deformed products, molding and granulation | CON40~63 |

| Parallel Type | Bidirectional rotation (slow rotation) | Hard PVC (or high viscosity resin) pipes, tubs, deformed products, for molding and granulation | TTS88~135 TTM98~168 | |

Basic configuration of the extruder

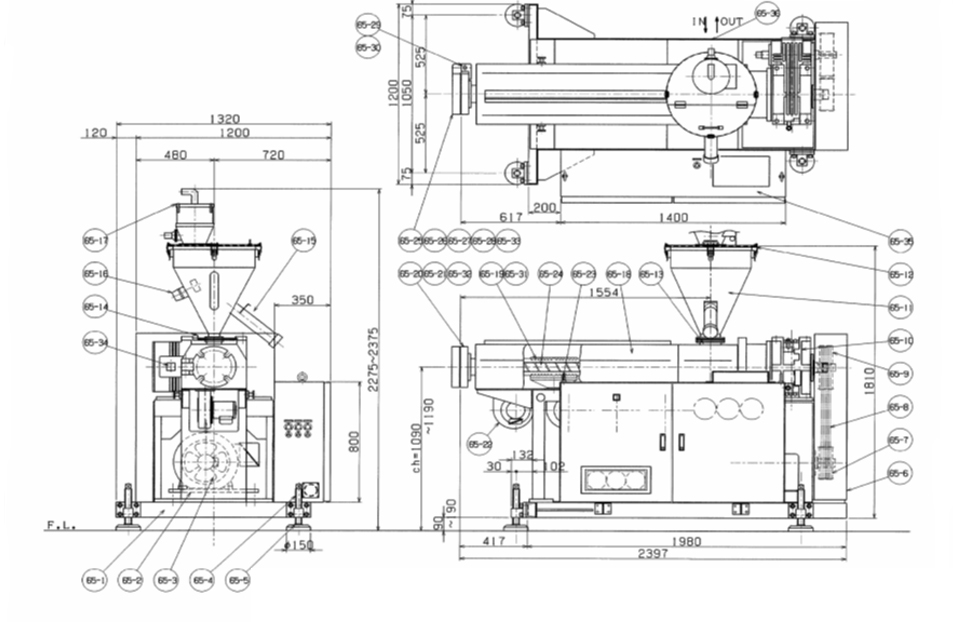

PMS65-25 Extruder Structure Diagram

| Number | Name |

|---|---|

| 65-01 | Frame (trestle) |

| 65-02 | Motorbase |

| 65-03 | Main motor (main motor) |

| 65-04 | Adjustable Bolt |

| 65-05 | Level Pads |

| 65-06 | Pulley Cover |

| 65-07 | Motor side pulley |

| 65-08 | Drive belt |

| 65-09 | Gearbox side pulley |

| 65-10 | Reducer (gearbox) |

| 65-11 | hopper |

| 65-12 | Loader mounting seat (base) |

| 65-13 | Material Supply Unit Throat |

| 65-14 | shutter |

| 65-15 | Material vent |

| 65-16 | Material level meter |

| 65-17 | Material feeding loader cyclone |

| 65-18 | Cylinder cover |

| Number | Name |

|---|---|

| 65-19 | Cylinder |

| 65-20 | Cylinder head plate |

| 65-21 | Breaker Plate |

| 65-22 | Cooling blower |

| 65-23 | Blower Duct |

| 65-24 | screw |

| 65-25 | Adapter Plate |

| 65-26 | eyebolt |

| 65-27 | nut |

| 65-28 | washer |

| 65-29 | hinge |

| 65-30 | Hinge Pins |

| 65-31 | Band Heater |

| 65-32 | Cylinder head ring heater |

| 65-33 | Ring space heater for adapter plate |

| 65-34 | Rotary encoder |

| 65-35 | Machine side type control cabinet |

| 65-36 | Hopper bottom cooling water supply and drainage port |

【Energy Saving Act】Improving the efficiency of motors in accordance with the Top Runner Standards

What are the Top Runner Criteria?

The Top Runner Standard is a measure within the Act on the Rational Use of Energy (Energy Conservation Act), which requires manufacturers to clear standards (such as target standards for energy consumption efficiency and the year in which they are achieved) for certain energy-saving products. Among the “specified equipment” for which this top runner standard is established, there were transformers in industrial electrical equipment, but three-phase induction motors have also been designated as specific equipment, and regulations began in April 2015.

What happens when a motor is subject to the Top Runner Criterion

The top-runner system is a regulation for manufacturers. Therefore, from April 2015, after the start of the regulation, the only motors to be shipped in Japan Japan will be high-efficiency motors (IE3: premium efficiency) that comply with the Top Runner regulations, and new products that are not compliant with the regulations IE1: standard efficiency and IE2: high efficiency (the high efficiency motor level currently prevalent in Japan) will not be sold.

* However, you can use a motor that is not highly efficient that you have already purchased.

・The target reference value (efficiency value) of the top runner standard is the efficiency class (JIS C 4034-30:2011) of the single-speed three-phase squirrrel-cage induction motor corresponding to “IE3: Premium efficiency”

of the following efficiency class *Consistent with IEC60034-30:2009

- IE3: Premium Efficiency

- IE2: High efficiency (high efficiency motor level currently popular in Japan)

- IE1: Standard efficiency