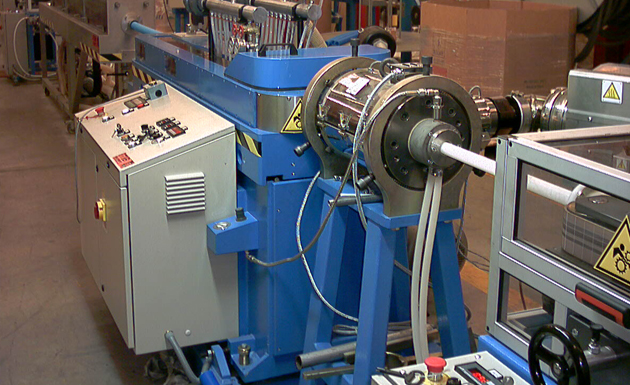

THEYSOHN (Austria)

We are a manufacturer of twin-screw extruders located in Austria. We have a proven track record in deformities, pipes, granulation, siding, etc. We provide motors and control panels domestically produced.

CON Series

The CON series of Tyson Conical extruders is used in a wide range of fields as molding machines for pipes, corrugated pipes, technical profiles, window frame products, etc. Today, its excellent screw design capabilities are also active in the dysmorphic form of all resins, including wood-powdered materials. It also demonstrates excellent performance as a granulator.

| Datasheet | unit | CON40 | CON50 | CON63 | CON68 | |

|---|---|---|---|---|---|---|

| Screw diameter [forward/rear] | mm | 40 / 85 | 50 / 108 | 63 / 130 | 68 / 141 | |

| Maximum screw speed | rpm | 41.5 | 41.0 | 34.0 | 32.0 | |

| Motor capacity *Made Japan | kW | Fifteen. | 22 | 37 | 45 | |

| Barrel temperature control point (heating/cooling) | Wow | 3 / 2 | 4 / 3 | 4 / 3 | 4 /3 | |

| Extruded mass | Plasticizing capability | kg/hr. | 100. | 200 | 300 | 350 |

| PVC Pipe | 10 – 85 | 30 – 180 | 50 -270 | 50 – 330 | ||

| PVC window frames | 10 – 65 | 30 – 125 | 50 -180 | 50 – 220 | ||

| R.PVC variant | 10 – 85 | 30 – 150 | 50 – 220 | 50 – 260 | ||

TTM-XT Series

The TTM-XT series of Tyson twin screw extruders is a parallel type bidirectional screw rotary twin-screw extruder. The TTM extruder is a high-torque next-generation model of the company's well-received PAR series. The maximum length of L/D30 and the optimum screw shape realize advanced and stable discharge.

| Datasheet | unit | TTM-XTP74 | TTM-XTR74 | TTM-XTR100 | TTM-XTR122 | |

|---|---|---|---|---|---|---|

| Screw diameter | mm | 74 | 74 | 100. | 122 | |

| Maximum screw speed | rpm | 32.2 | 48 | 34.9 | 29 | |

| Motor capacity | kW | 33 | 49 | 85 | 129 | |

| Barrel temperature control point | Heating/cooling | 5 / 3 | 5 / 3 | 5 / 3 | 6 / 3 | |

| Extruded mass | Plasticizing capability | kg/hr. | 350 | 490 | 870 | 1320 |

| R.PVC Pipe | – | 150 – 450 | 250 – 790 | 400 – 1200 | ||

| PVC window frames | 100 – 290 | – | – | – | ||

| R.PVC variant | 100 – 315 | – | – | – | ||

XTS-P/ XTS-R Series

The XTS-P/XTS-R series are parallel type anidirectional screw rotary twin-shaft extruders. We use the latest technology to enable a simple and flexible extrusion process. In particular, by improving the shape of the gearbox, we have achieved a high energy reduction rate. It also demonstrates excellent performance as a granulator.

| Item | unit | XTS88P-26 | XTS88P-32 | XTS108P-32 | XTS122P-28 | |

|---|---|---|---|---|---|---|

| Screw diameter | mm | 88 | 88 | 108 | 122 | |

| L / D | – | 26 | 32 | 32 | 28 | |

| Maximum screw speed | rpm | 26.4 | 26.4 | 21.7 | 19.1 | |

| Motor capacity | kW | 34.7 | 45.3 | 66.7 | 85.0 | |

| Barrel temperature control point | Heating/cooling | 5 / 3 | 6 / 3 | 6 / 3 | 6 / 3 | |

| Extruded mass | Plasticizing capability | kg/hr. | 360 | 490 | 720 | 920 |

| PVC window frames | 80 – 300 | 135 – 390 | 200 – 600 | 300 – 760 | ||

| R.PVC variant | 80 – 340 | 135 – 440 | 200 – 650 | 250 -840 | ||

Example of pipe molding (XTS-R series) specifications;

| Item | unit | XTS88R-26 | XTS88R-36 | XTS108R-36 | XTS122R-36 | |

|---|---|---|---|---|---|---|

| Screw diameter | mm | 88 | 88 | 108 | 122 | |

| Maximum screw speed | rpm | 40.0 | 40.0 | 36.0 | 29.0 | |

| Motor capacity | kW | 48.0 | 68.0 | 129 | 129 | |

| Barrel temperature control point | Heating/cooling | 5 / 3 | 6 / 3 | 6 / 3 | 6 / 3 | |

| Extruded mass | Plasticizing capability | kg/hr. | 480 | 700 | 1050 | 1320 |

| R.PVC Pipe | 120 – 420 | 200 – 620 | 320 – 950 | 400 – 1200 | ||

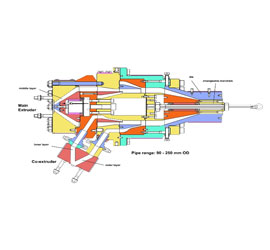

IDE (Germany)

IDE is a manufacturer that offers extrusion lines for all profiles in Germany. We design, develop and manufacture individually based on customer requests. We also provide equipment to handle large-scale variants that are difficult in Japan.

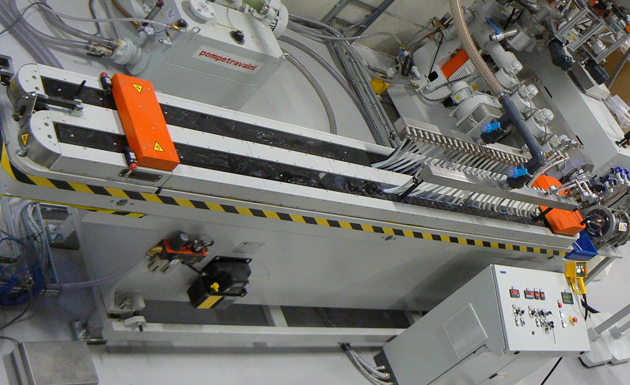

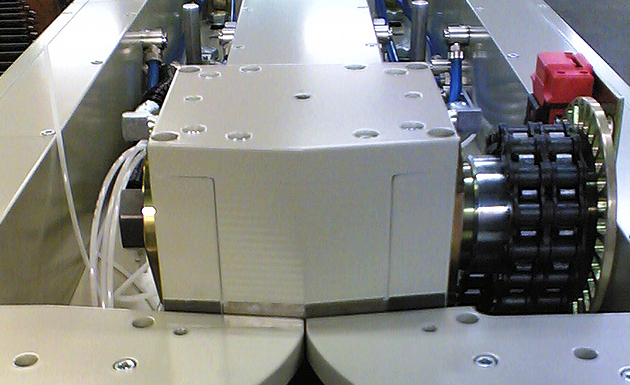

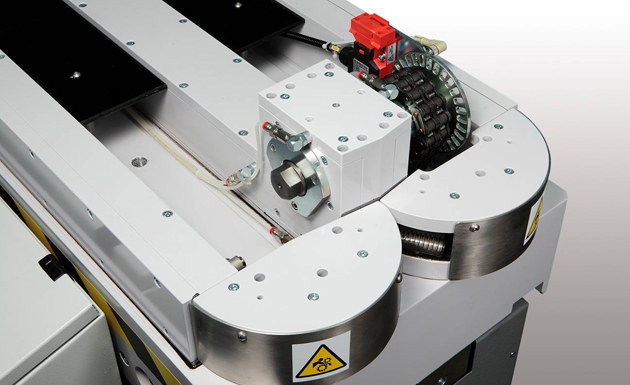

Calibration unit

IDE calibration units are characterized by a rigid mechanical construction and a flexible adjustable mounting platform. Mounting platforms of various lengths and widths are available to accommodate all calibrators (sizing formers) and cooling systems.

ITIB (Italy)

ITIB is a professional manufacturer of plastic corrugators in Italy. We provide corrugated equipment and lines compatible with various materials such as PE, PP, PVC, PA, EVA, and PVDF all over the world.

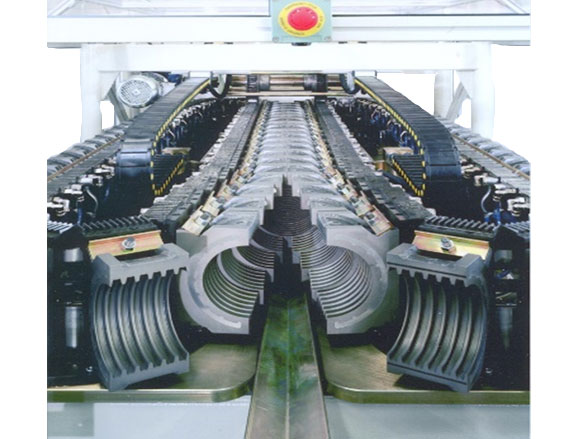

Corrugated pipe manufacturing equipment (corrugator)

By connecting molding molds that have been split in two into a caterpillar type, corrugated pipes are manufactured. This is a manufacturing device for molding single- or double-layer corrugated tubes. It accommodates a wide range of sizes from a minimum inner diameter of 4.5 mm to a maximum outer diameter of 1200 mm. There are two types of molding methods: air pressure method and vacuum suction method. Upon request, peripheral devices such as mouthpiece die sets, winding machines and drilling machines are also available.