Precision single-shaft extruder

It is ideal for precision and stable extrusion molding from general-purpose resins to super engineering plastic resins.

In particular, by supporting various estramer resins and adding various optional specifications to the standard machine, we can perform low-temperature, stable, and high-discharge extrusion for extruders of each size.

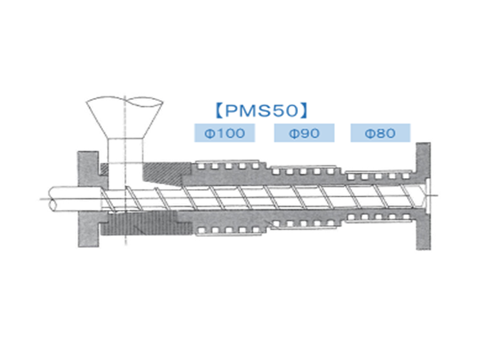

PMS Series

High discharge extruder for olefin resins

This extruder combines a highly effective heating and cooling cylinder shape with a variety of screw shapes.

The extruder is highly effective for general-purpose resins as well as super engineering plastic resins.

Low-temperature plasticization is made possible by a simplified forced-feed mechanism (hopper block, brake block specification, and grooved cylinder) for high-speed extrusion.

The main electric motor is controlled by an inverter for stable extrusion and maintenance-free operation.

PMS Extruder Specifications

| Item/Model | PMS18 | PMS20 | PMS25 | PMS30 | PMS40 | PMS50 | PMS65 | PMS75 | PMS80 | PMS90 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| L/D | 25~28 | 25~28 | 25~28 | 25~28 | 25~28 | 25~32 | 25~32 | 25~32 | 25~32 | 25~32 | |

| Motor capacity | 0.75~2.2 | 1.5~2.2 | 2.2~3.7 | 3.7~7.5 | 5.5~15 | 11~22 | 22~45 | 30~75 | 37~90 | 45~110 | |

| Extrusion ( kg/h) | Olefins | 1~3 | 1~3 | 1~5 | 5~15 | 10~30 | 20~60 | 40~140 | 60~180 | 70~210 | 80~260 |

| Empra | 1~2.5 | 1~2.5 | 1~4 | 5~10 | 10~25 | 20~40 | 40~80 | 60~110 | 70~130 | 80~150 | |

PMS Series

High discharge extruder for olefin resin

- A cylinder with special groove processing is used to achieve low-temperature plasticization and a significant increase in extrusion volume.

- The size of the extruder can be reduced, saving space and energy.

- Ideal for forming pipe tubes, sheets and films of olefin resins such as soft PP and PE.

| Item/Model | PMSG65 | PMSG75 | PMSG90 | PMSG100 | PMSG115 | |

|---|---|---|---|---|---|---|

| L/D | 27/30 | 27/30 | 27/30 | 27/30 | 27/30 | |

| Motor capacity (kW) | 55~75 | 75~110 | 90~160 | 132~160 | 160~250 | |

| Screw speed (rpm) | 150~200 | 125~180 | 100~145 | 85~120 | 70~110 | |

| Extrusion ( kg/h) | HDPE | 160~210 | 220~320 | 330~480 | 350~500 | 390~610 |

| Pp | 140~180 | 190~270 | 280~400 | 290~420 | 330~520 | |

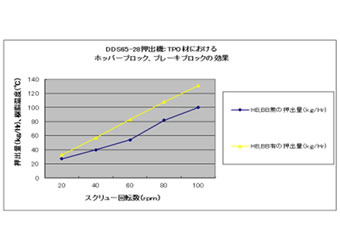

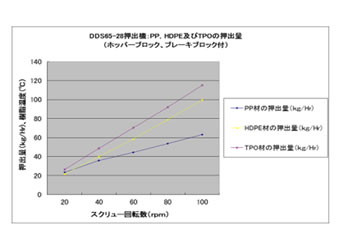

DDS Series

Direct-drive extruder

- Clean: No dust on the drive belt

- No vibration: no vibration due to pulley and belt drive

- Low noise: no vibration noise of the drive belt

- Compact: no pulley, pulley cover

- Maintenance-free: no need to replace or adjust the drive belt

DDS Extruder Specifications

| Item/Model | DDS50 | DDS65 | DDS75 | |||

|---|---|---|---|---|---|---|

| L/D | 25~32 | 25~32 | 25~32 | |||

| Motor capacity (kW) | 18.5 | 22 | 30 | 37 | 37 | 45 |

| Screw speed (rpm) | 60 | 100. | 60 | 100. | 60 | 100. |

MS Series

High-performance single-shaft extruder (large)

- Large type with cylinder diameter 100 mm ~ 300 mm.

MS Extruder Specifications

| Item/Model | MS100 | MS115 | MS125 | MS150 | MS180 | MS200 | MS300 |

|---|---|---|---|---|---|---|---|

| L/D | 25~34 | 25~34 | 25~34 | 25~34 | 25~34 | 25~34 | 25~34 |

| Motor capacity (kW) | 75~110 | 90~110 | 90~115 | 100~150 | 110~170 | 150~230 | 170~450 |

| Extrusion (kg/h) | 100~300 | 130~360 | 140~420 | 300~500 | 500~800 | 700~1,000 | 1,000~1,800 |

MSZII Series

Dry-free energy-saving single-shaft extruder: Special 3-vent port type extruder

- This extruder is for non-drying molding of resins that require pre-drying of PET-G, ABS, PMMA, wood flour composite materials, etc.

- No need for hot air or dehumidifying dryer equipment.

- Since drying is not required, “energy saving”, “process reduction” and “space saving”.

- Since it is possible to perform up to 3 vents, the machine specifications according to the resin and application are selected, and non-drying extrusion is performed.

- Quality improvement by venting effect.

- Reduction of eye burning.

MSZII Extruder Specifications

| Item/Model | MSZⅡ40 | MSZⅡ50 | MSZⅡ65 | MSZⅡ75 |

|---|---|---|---|---|

| L/D | 32~38 | 32~38 | 32~38 | 32~38 |

| Motor capacity (kW) | 5.5~15 | 11~22 | 22~45 | 30~75 |

| Number of vent ports | 1~3 | 1~3 | 1~3 | 1~3 |

KMS Series Miniature Extruder for Extremely Small Volumes

| Extremely small volume extruder |

| Suitable for extrusion volume from 150cc/hr position of extruder for very small quantities suitable for medical use, research use, etc . |

KMS Extruder Specifications

| Item/Model | KMS12 | KMS15 |

|---|---|---|

| Screw diameter (mm) | φ12mm | φ15mm |

| L/D | 25 | 25 |

| Motor capacity (kW) | 0.75 | 0.75 |

| Screw speed (rpm) | 60 | 60 |

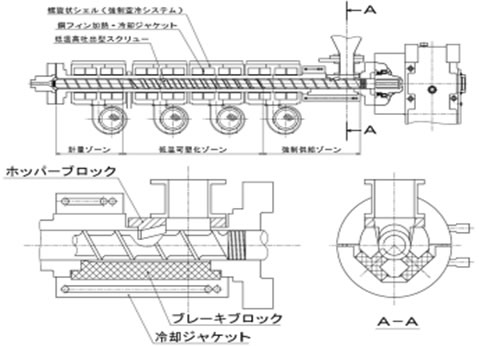

Brake Block, Hopper Block

Improvement of stability of raw material ingestionImproved

stability of individual transport volumeImprovement of extrusion amount

of resin of

soft system and pulverized resin Enables detachment and detachment (smooth block can be attached)

Single shaft extruder optional

Structure Diagram

Stepped cylinder

| The outer diameter of the cylinder is changed to a different diameter for each section, improving the resin temperature control performance of each zone. |

| ・Improvement of heating and cooling efficiency, stable resin temperature , screw rotation speed can be increased |

Structure Diagram

CEL/CEL-A Series Space-saving extruder for composite type two-color molding

| Space-saving type composite type extruder for two-color molding |

| Space-saving: A sub-extruder that can be moved up, down, forward, backward, and swiveling is placed on top of the main extruder. Mold set: Easy to core out with the same frame. Interlocking control: By adopting “FORWARD ED6”, multi-layer extrusion and interlocking of the collection machine are possible. Ideal for early product launch and management. There are two types: “CEL type” of orthogonal type and “CEL-A” of oblique type. Combination of bi-color extruder |

Type

| Orthogonal type | CEL Type |

| Oblique | CEL-A Type |

Combination of bi-color extruder

| Main PMS | 40,50,65,75,90 |

| Sub-MVS | 30,40,50 |

DHS Series Direct Drive Type Strut Type Upper and Lower Lifting Sub-Extruder

| Direct drive type prop type vertical and lowering sub-extruder |

| By directly connecting the motor and the gearbox, we have improved the space saving and operability required for sub-extruders. |

DHS Extruder Specifications

| Item/Model | DHS25 | DHS30 | DHS40 |

|---|---|---|---|

| L/D | 25 | 25~28 | 25~28 |

| Screw speed (rpm) | 60/85 | 60/85 | 60/85 |

| Motor capacity (kW) | 2.2 | 3.7 | 7.5 |

| Raising and lowering | Electric type (stroke: 500mm) | ||

| Turning | manual | ||

| Temperature control panel | Free-standing caster type | ||

| Optional: Cylinder front and rear mobile | Manual stroke 100 mm | ||

MVS Series MVS Series Pole Type Vertical Elevating Sub-Extruder

| MVS series pillar type vertical elevating sub-extruder Extruder with frame specification corresponding to each factory layout. We have designed 3 types according to customer needs. H type: Extruder body set horizontally (left photo) V-type; Extruder body set vertically Type A: Extruder body set at an angle |

MVS Extruder Specifications

| Item/Model | MVS20 | MVS25 | MVS30 | MVS40 | MVS50 | MVS65 |

|---|---|---|---|---|---|---|

| L/D | 25/28 | 25/28 | 25/28 | 25/28 | 25/28 | 25/28 |

| Motor capacity (kW) | 1.5~2.2 | 2.2~3.7 | 3.7~5.5 | 5.5~11 | 11~22 | 22~45 |

| Raising and lowering | Electric type (stroke: 500mm) | |||||

| Turning | manual | |||||

| Temperature control panel | Free-standing caster type | |||||