Control unit

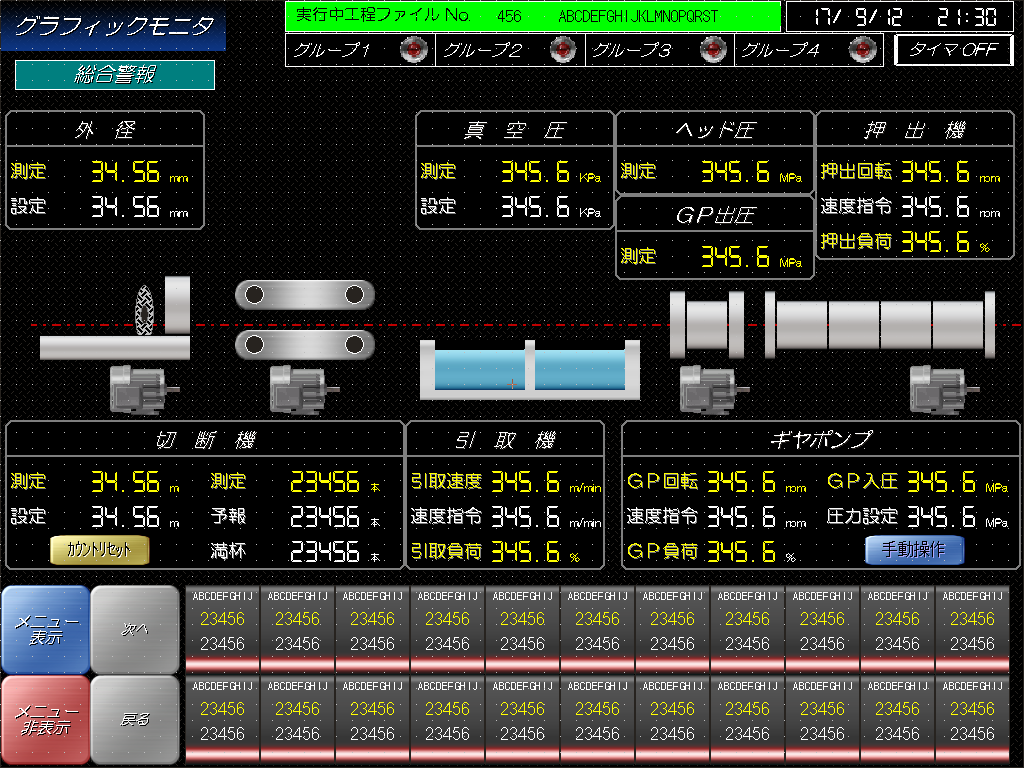

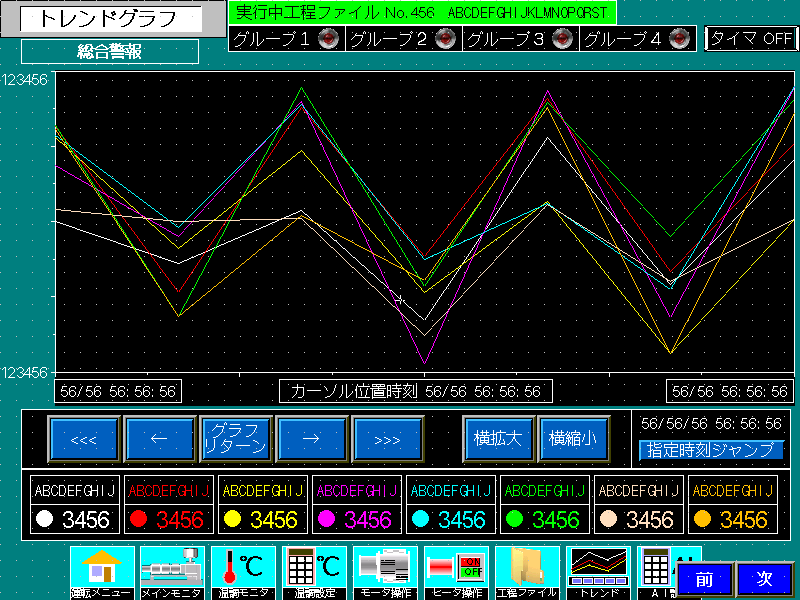

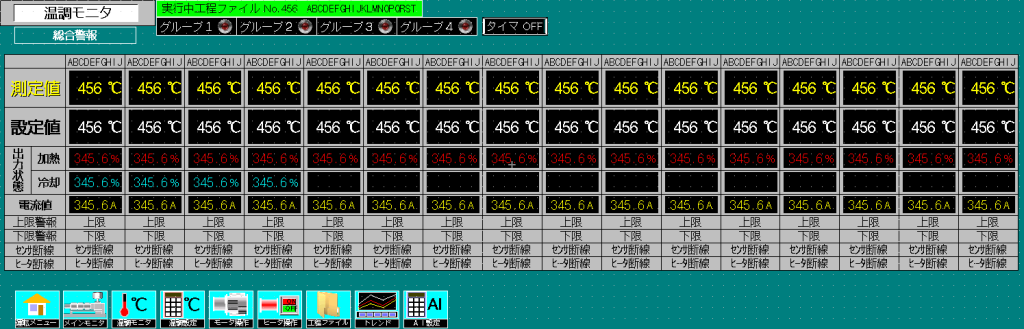

FORWARD-ExLC

Extruder Line Controller

- 12.1-inch TFT display achieves both comfort and visibility

- Use off-the-shelf hardware and consider long-term maintenance

- Feedback control such as ratio control and pressure control by multiple extruders and each ancillary device is standard equipment

- By using ready-made tool software, it is possible to manage the data of the molding line on a personal computer.

- Number of motor control points: Up to 4 points

- Temperature control score: Up to 128 points (64 points in the case of heating and cooling)

FORWARD-ExLC Specification

Standard Features | ・Various feedback controls , trend graph functions, calendar timer functions, heater disconnection functions, process file functions |

FORWARD ED-Ⅵ

A multifunctional PLC (process controller) that is effective in labor-saving and streamlining such as extruder controller

, production management and process control of extrusion lines.

・ TFT color 10.4 inch LCD screen for easy viewing operation.

・Use ready-made touch panels, PLCs, and temperature controls, and consider long-term maintenance.

・ It is possible to use ready-made hardware to make it difficult to break, standardize the system, and flexibly respond to custom-made specifications.

・ Up to 6 FORWARDs can be centrally managed on a personal computer (control is not possible). 〔Optional specification〕

FORWARD ED-VI Specification

| Standard Features | ・Process file function, trend graph function, external memory function, printer output function : for hard copy |

| option | ・Number of temperature control points: 64 points, Number of motor control points: Up to 4 points , Screen UP size: 12 inches ・Function: Heater disconnection function, form creation, printing function, host communication function |

| Special Features | ・ Supports pressure control, Japanese, and English display, and the number of motor control points: 5 points or more * Other special specifications are also supported. |

Peripherals

| We handle peripheral equipment of extrusion molding lines. |

| ・Extruder mounting equipment: Gear pump unit, screen changer, material-related equipment: Dehumidification dryer, hot air dryer, material mixer, material air feeder (loader ), temperature control related equipment: chiller unit , mold temperature controller |